Customizing fire hoses is crucial for achieving optimal performance in a wide range of applications. Whether for firefighting or industrial use, each scenario requires specific features to address its unique demands. For example, in 2020, fire hoses played a vital role in over 70% of forest fire areas across the US, achieving an impressive 95% success rate in controlling these fires. This demonstrates how tailored solutions can greatly enhance operational efficiency.

Fire hoses are available in various sizes, including DN25-DN100, and are made from durable materials such as PVC, PU, and EPDM. These material and size options enable us to adapt hoses to specific pressure requirements, flow rates, and environmental conditions. By customizing features like length, diameter, and couplings, we ensure compatibility with equipment and adherence to local standards. This not only enhances safety but also increases the durability and lifespan of the firehose.

Key Takeaways

- Changing fire hoses makes them work better for special tasks.

- Picking materials like PVC, PU, or EPDM makes hoses strong.

- Knowing pressure and flow needs helps hoses work well in emergencies.

- Checking and fixing hoses often keeps them safe and lasts longer.

- Writing down changes and fixes helps find problems early.

Assessing Application Needs

Identifying the Purpose

Firefighting Applications

When customizing a firehose for firefighting, I always start by considering its primary purpose. Firefighting requires hoses that can handle high-pressure water delivery and withstand extreme conditions. For example, in 2020, fire hoses were instrumental in controlling over 70% of forest fire areas in the US, achieving a success rate exceeding 95%. This highlights the importance of using durable and efficient hoses in such critical scenarios. Materials like PVC, PU, and EPDM are commonly used due to their ability to endure high temperatures and resist wear during deployment.

Industrial and Agricultural Uses

In industrial and agricultural settings, fire hoses serve a broader range of purposes. These include irrigation, chemical transfer, and dust suppression. The construction and industrial sectors have driven global demand for fire hoses, especially in emerging economies where building activities are rapidly increasing. I ensure that hoses for these applications meet specific requirements, such as chemical resistance and flexibility, to perform effectively in diverse environments.

Determining Key Requirements

Pressure and Flow Rate Needs

Understanding pressure and flow rate requirements is essential. For instance, attack hoses must withstand operational pressures of up to 300 psi, while fire pumps should produce at least 65% of rated pressure at 150% of rated flow. I always verify these specifications to ensure the hose delivers optimal performance during emergencies.

| Specification Type | Details |

|---|---|

| Pressure Testing | Hoses must withstand specified operational pressures (e.g., 300 psi). |

| Flow Rate Requirements | Fire pumps should produce at least 65% of rated pressure at 150% flow. |

| Nozzle Specifications | Nozzles must deliver specific gallonage at rated pressures (e.g., 60 GPM at 100 PSI). |

Length and Diameter Considerations (DN25-DN100)

The length and diameter of a firehose significantly impact its performance. I typically recommend sizes ranging from DN25 to DN100, depending on the application. Smaller diameters are ideal for residential or light industrial use, while larger diameters suit high-flow requirements in firefighting or agricultural irrigation.

Understanding Environmental Factors

Temperature and Weather Resistance

Environmental conditions play a crucial role in hose selection. Fire hoses must withstand extreme temperatures and adverse weather. For instance, heat resistance ensures functionality in high-temperature fire environments, while abrasion resistance protects against rough surfaces. These factors directly influence the hose’s durability and effectiveness.

| Performance Indicator | Description |

|---|---|

| Heat resistance | The capability to function in high-temperature environments. |

| Abrasion resistance | The ability to resist wear and tear from rough surfaces. |

Chemical Exposure and Durability

In industrial applications, hoses often encounter chemicals that can cause corrosion. I prioritize materials like EPDM and PU for their superior chemical resistance. This ensures the hose remains functional and durable, even in harsh conditions. Regular maintenance and inspections also help prevent premature deterioration.

Choosing the Right Hose Type

Overview of Fire Hose Materials

PVC, PU, and EPDM materials

When selecting a firehose, I always consider the material first. PVC, PU, and EPDM are the most common materials due to their durability and adaptability. PVC hoses are lightweight and cost-effective, making them suitable for general-purpose applications. PU hoses, on the other hand, offer excellent flexibility and abrasion resistance, which is ideal for industrial and agricultural use. EPDM hoses excel in extreme conditions, providing superior heat and chemical resistance.

Pros and cons of each material

Each material has its strengths and limitations. To help you decide, I’ve summarized their performance in the table below:

| Material | Advantages | Disadvantages |

|---|---|---|

| PVC | Lightweight, affordable | Less heat and abrasion resistant |

| PU | Flexible, abrasion-resistant | Higher cost |

| EPDM | Heat and chemical resistant | Heavier, more expensive |

Selecting the Appropriate Size

Common diameters (DN25-DN100) and their uses

Fire hoses come in various sizes, typically ranging from DN25 to DN100. Smaller diameters, such as DN25 and DN40, are perfect for residential or light industrial use. Larger diameters, like DN65 and DN100, are better suited for high-flow applications, such as firefighting or large-scale irrigation.

Matching size to application needs

Choosing the right size depends on the required flow rate and pressure. For example, a 1½-inch hose delivers 200 gallons per minute (gpm) at 50 psi but experiences a friction loss of 96 psi per 100 feet. In contrast, a 1¾-inch hose maintains the same flow rate and pressure with a reduced friction loss of 62 psi per 100 feet. This demonstrates how larger diameters can improve efficiency during operations.

| Hose Size | Flow Rate (gpm) | Nozzle Pressure (psi) | Friction Loss (psi/100ft) |

|---|---|---|---|

| 1½-inch | 200 | 50 | 96 |

| 1¾-inch | 200 | 50 | 62 |

Considering Hose Color and Standards

White vs. red hoses

The color of a firehose often indicates its intended use. White hoses are typically used for industrial or agricultural purposes, while red hoses are standard for firefighting. I always ensure the color aligns with the application to avoid confusion during emergencies.

Local fire protection standards

Compliance with local fire protection standards is non-negotiable. These standards dictate not only the hose’s performance but also its compatibility with hydrants and couplings. For instance, NFPA guidelines ensure operational readiness and legal compliance, which are critical for liability and insurance purposes.

| Aspect | Description |

|---|---|

| NFPA Standards | Provide guidelines for fire hose inspections and maintenance, ensuring operational readiness. |

| Legal Requirements | Compliance is often mandated by law, affecting liability and insurance considerations. |

| Hydrant Color Coding | NFPA defines a color coding system for hydrants, but local jurisdictions may have their own variations. |

Customizing Hose Features

Modifying Couplings

Types of couplings (threaded, quick-connect, etc.)

Couplings play a critical role in ensuring a firehose connects seamlessly to other equipment. I often choose between threaded and quick-connect couplings based on the application. Threaded couplings, such as NH (National Hose) or BSP (British Standard Pipe), provide a secure and leak-proof connection, making them ideal for high-pressure scenarios. Quick-connect couplings, on the other hand, allow for rapid attachment and detachment, which is essential during emergencies. Both types are available in materials like brass or aluminum for durability.

Ensuring compatibility with equipment

When customizing couplings, I always verify their compatibility with existing equipment. This involves checking the thread type, size, and local fire protection standards. For instance, a DN65 firehose with a quick-connect coupling must match the hydrant’s specifications to ensure a proper fit. This step prevents delays during critical operations and enhances overall efficiency.

Adjusting Nozzles

Types of nozzles and their functions

Nozzles determine how water is delivered during operations. I typically work with smooth bore and combination nozzles. Smooth bore nozzles provide a concentrated stream, making them effective for long-distance water delivery. Combination nozzles offer versatility, allowing users to switch between straight streams and fog patterns. This flexibility proves invaluable in scenarios requiring both precision and area coverage.

| Nozzle Type | Flow Rate (lpm) | Pressure (bar) | Impact Measurement (kgs/force) |

|---|---|---|---|

| Smooth Bore (22mm) | 600 | 3.5 | [Impact Data] |

| Smooth Bore (19mm) | 600 | 7 | [Impact Data] |

| Combination Nozzle | 600 | 3.5, 5, 7 | [Impact Data] |

Selecting nozzles for specific tasks

Choosing the right nozzle depends on the task at hand. For example, I recommend smooth bore nozzles for firefighting in open areas due to their high impact force. Combination nozzles work better in confined spaces where fog patterns can suppress flames and reduce heat. Matching the nozzle type to the application ensures optimal performance and safety.

Tailoring Length and Diameter

Cutting hoses to the desired length

Customizing the length of a firehose enhances its usability. I often cut hoses to specific lengths based on operational needs. For instance, a 200-foot hose is ideal for urban firefighting, while shorter lengths suit industrial applications. Proper cutting techniques ensure clean edges, preventing leaks and maintaining structural integrity.

Adjusting diameter for flow requirements

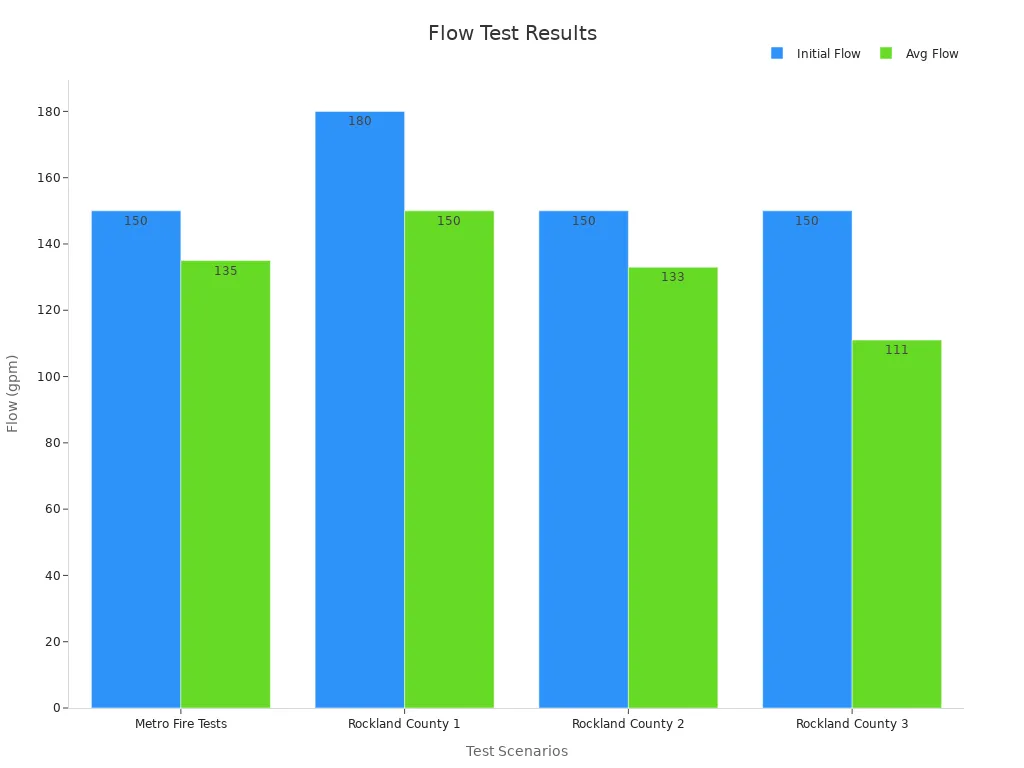

The diameter of a firehose directly impacts its flow rate and pressure. I typically recommend sizes ranging from DN25 to DN100, depending on the application. Case studies, such as the Metro Fire Tests, highlight how altering hose length and diameter optimizes flow. For example, a 150-foot hose with a 15/16-inch smooth bore nozzle delivers 180 gpm at 50 psi but drops to 150 gpm with kinks. This data underscores the importance of selecting the right diameter for consistent performance.

Testing and Quality Assurance

Conducting Performance Tests

Pressure testing for leaks

I always begin quality assurance by conducting pressure tests to identify potential leaks. This process involves subjecting the hose to operational pressures higher than its rated capacity. For example, attack hoses rated at 300 psi undergo testing at 400 psi to ensure durability under extreme conditions. This step guarantees that the hose can handle emergencies without failure.

Flow rate verification

Flow rate testing is equally critical. I measure the water delivery rate under various nozzle pressures to confirm the hose meets performance standards. The table below highlights typical results from flow rate tests:

| Test Condition | Average Flow (gpm) | Nozzle Pressure (psi) |

|---|---|---|

| 50 psi fog | 135 (Metro) / 133 (Rockland) | 50 |

| 75 psi fog | 118 (Metro) | 75 |

| 100 psi fog | 111 (Rockland) | 100 |

| Minimum Target Flow | 185 gpm | 75 |

These tests ensure the hose delivers consistent performance, even under varying conditions.

Ensuring Safety Standards

Compliance with local regulations

Adhering to local safety regulations is non-negotiable. I follow NFPA 1962 guidelines, which outline inspection and testing requirements for fire hoses. These standards ensure operational readiness and legal compliance. Regular testing prevents failures that could lead to dangerous situations, such as hoses whipping uncontrollably during use.

Inspecting for material defects

Visual inspections play a vital role in maintaining safety. I check for damage, wear, and other defects that could compromise the hose’s integrity. This step ensures the hose remains functional under extreme conditions, protecting both firefighters and civilians.

Tip: Regular inspections and adherence to NFPA standards enhance safety and extend the lifespan of fire hoses.

Documenting Customization

Keeping records of modifications

I maintain detailed records of all customizations, including changes to length, diameter, and couplings. These records provide a clear history of modifications, which is essential for future maintenance and troubleshooting.

Creating a maintenance log

A well-organized maintenance log tracks performance trends and identifies potential issues early. I update this log regularly, noting inspections, repairs, and performance audits. This systematic approach ensures informed decision-making and continuous improvement.

Note: Accurate documentation not only enhances operational efficiency but also reduces long-term maintenance costs.

Maintenance and Upkeep

Cleaning and Storage

Proper cleaning techniques for different materials

Cleaning fire hoses properly is essential to maintain their functionality and extend their lifespan. I always follow manufacturer recommendations for cleaning and drying, as this ensures the materials retain their integrity. For hoses made of PVC, a mild detergent and warm water work best to remove dirt and debris. PU and EPDM hoses, being more resistant to chemicals, can handle stronger cleaning agents when necessary. After cleaning, I ensure the hoses are thoroughly dried to prevent mold or mildew growth.

- Proper storage prevents deterioration and ensures safety.

- Adequate airflow during storage dissipates harmful substances absorbed by the hose.

- Following cleaning guidelines prolongs the functional life of the hose.

Storing hoses to prevent damage

Storage plays a critical role in preserving fire hoses. I always store hoses in a cool, dry place, away from direct sunlight or extreme temperatures. Hanging hoses on racks prevents kinks and reduces stress on the material. For long-term storage, I recommend rolling the hoses loosely to maintain their shape and avoid unnecessary strain.

Regular Inspections

Checking for wear and tear

Regular inspections help identify potential issues before they escalate. I examine hoses for cracks, abrasions, or signs of corrosion. Fittings are checked for tightness and leaks, while the system pressure is monitored for irregularities. The table below outlines key focus areas for inspections:

| Maintenance Focus Area | Recommendations |

|---|---|

| Tube Integrity | Check for cracks, wear, or corrosion. |

| Fittings | Inspect for tightness and leakage. |

| System Pressure | Monitor for irregularities. |

| Temperature Monitoring | Use sensors to maintain optimal levels. |

| Pressure Control | Operate within specified pressure ranges. |

| Chemical Exposure | Use protective coatings and clean often. |

Replacing damaged components

When I find damaged components, I replace them immediately to avoid compromising the hose’s performance. For example, worn-out couplings or nozzles can lead to leaks or reduced efficiency. Prompt replacement ensures the hose remains operational during emergencies.

Extending Hose Lifespan

Tips for preventing premature wear

Preventing premature wear requires a proactive approach. I avoid dragging hoses across rough surfaces and ensure they are not exposed to sharp objects. Using protective sleeves in high-abrasion areas minimizes damage. Regular cleaning and proper storage also play a significant role in extending the hose’s service life.

Scheduling professional maintenance

Scheduling professional maintenance is vital for ensuring reliability. Trained personnel conduct visual inspections and pressure tests to identify hidden issues. Adhering to NFPA standards during these inspections guarantees the hose’s integrity. I recommend establishing clear maintenance protocols and allocating resources for proper equipment and skilled technicians. Regular maintenance not only prevents failures but also enhances the hose’s effectiveness during critical operations.

Tip: Consistent maintenance and professional inspections significantly reduce the risk of hose failure, ensuring safety and reliability.

Customizing fire hoses involves several critical steps, from assessing application needs to selecting the right materials, sizes, and features. Testing and maintenance ensure these hoses perform reliably during emergencies. Regular inspections and adherence to safety standards prevent failures and extend their lifespan.

- In 2020, fire hoses controlled over 70% of forest fire areas in the U.S., achieving a 95% success rate. However, improper use and maintenance remain challenges.

- Stringent fire safety regulations and NFPA standards highlight the need for professional expertise in complex modifications.

Consulting specialists ensures compliance, safety, and optimal performance in high-stakes scenarios.

FAQ

What is the standard working pressure range for fire hoses?

The standard working pressure for fire hoses typically ranges from 8 bar to 18 bar. I always recommend verifying the pressure requirements based on the intended application to ensure safety and optimal performance.

Can fire hoses be customized for specific lengths and diameters?

Yes, fire hoses can be tailored to specific lengths and diameters, ranging from DN25 to DN100. I cut hoses to the desired length and adjust diameters to meet flow and pressure requirements for various applications.

What materials are commonly used for fire hoses?

Fire hoses are often made from PVC, PU, or EPDM. Each material offers unique benefits. For instance, PVC is lightweight, PU is abrasion-resistant, and EPDM excels in heat and chemical resistance. I select materials based on environmental and operational needs.

How do I ensure compatibility between hoses and couplings?

To ensure compatibility, I check the coupling type, thread size, and local fire protection standards. Matching these specifications guarantees a secure connection and prevents delays during critical operations.

Why are fire hoses available in different colors?

Fire hoses come in white or red to indicate their use. White hoses are typically for industrial or agricultural purposes, while red hoses are standard for firefighting. I always align the color with the application to avoid confusion during emergencies.

Post time: Mar-15-2025